Turbine Operation Models#

Separate from the turbine models, which define the physical characterstics of the turbines, FLORIS

allows users to specify how the turbine behaves in terms of producing power and thurst. We refer to

different models for turbine behavior as "operation models". A key feature of operation models is

the ability for users to specify control setpoints at which the operation model will be evaluated.

For instance, some operation models allow users to specify yaw_angles, which alter the power

being produced by the turbine along with it's thrust force on flow.

Operation models are specified by the operation_model key on the turbine yaml file, or by using

the set_operation_model() method on FlorisModel. Each operation model available in FLORIS is

described and demonstrated below. The simplest operation model is the "simple" operation model,

which takes no control setpoints and simply evaluates the power and thrust coefficient curves for

the turbine at the current wind condition. The default operation model is the "cosine-loss"

operation model, which models the loss in power of a turbine under yaw misalignment using a cosine

term with an exponent.

We first provide a quick demonstration of how to switch between different operation models. Then,

each operation model available in FLORIS is described, along with its relevant control setpoints.

We also describe the different parameters that must be specified in the turbine

"power_thrust_table" dictionary in order to use that operation model.

Selecting the operation model#

There are two options for selecting the operation model:

Manually changing the

"operation_model"field of the turbine input yaml (see Turbine Input File Reference)Using

set_operation_model()on an instantiatedFlorisModelobject.

The following code demonstrates the use of the second option.

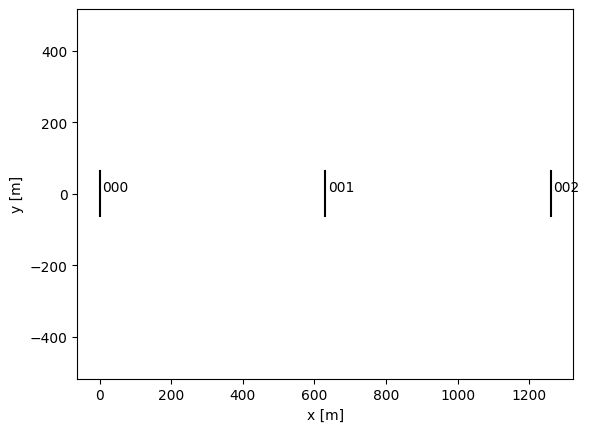

from floris import FlorisModel

from floris import layout_visualization as layoutviz

fmodel = FlorisModel("../examples/inputs/gch.yaml")

# Look at layout

ax = layoutviz.plot_turbine_rotors(fmodel)

layoutviz.plot_turbine_labels(fmodel, ax=ax)

ax.set_xlabel("x [m]")

ax.set_ylabel("y [m]")

# Set simple operation model

fmodel.set_operation_model("simple")

# Evalaute the model and extract the power output

fmodel.run()

print("simple operation model powers [kW]: ", fmodel.get_turbine_powers() / 1000)

# Set the yaw angles (which the "simple" operation model does not use

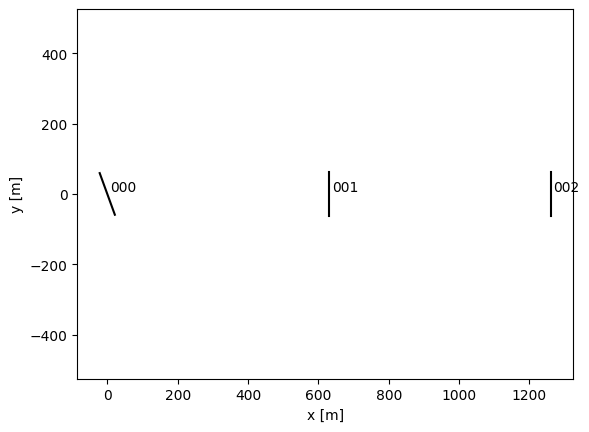

# and change the operation model to "cosine-loss"

fmodel.set(yaw_angles=[[20., 0., 0.]])

fmodel.set_operation_model("cosine-loss")

ax = layoutviz.plot_turbine_rotors(fmodel)

layoutviz.plot_turbine_labels(fmodel, ax=ax)

ax.set_xlabel("x [m]")

ax.set_ylabel("y [m]")

# Evaluate again

fmodel.run()

powers_cosine_loss = fmodel.get_turbine_powers()

print("cosine-loss operation model powers [kW]: ", fmodel.get_turbine_powers() / 1000)

/home/runner/work/floris/floris/floris/core/flow_field.py:169: UserWarning: 'where' used without 'out', expect unitialized memory in output. If this is intentional, use out=None.

* np.power(

simple operation model powers [kW]: [[1753.95445918 436.4427005 506.66815478]]

cosine-loss operation model powers [kW]: [[1561.31837381 778.04338242 651.77709894]]

Operation model library#

Simple model#

User-level name: "simple"

Underlying class: SimpleTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)

The "simple" operation model describes the "normal" function of a wind turbine, as described by

its power curve and thrust coefficient. It does not respond to any control setpoints, and is most

often used as a baseline or for users wanting to evaluate wind farms in nominal operation.

Cosine loss model#

User-level name: "cosine-loss"

Underlying class: CosineLossTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)cosine_loss_exponent_yaw(scalar)cosine_loss_exponent_tilt(scalar)

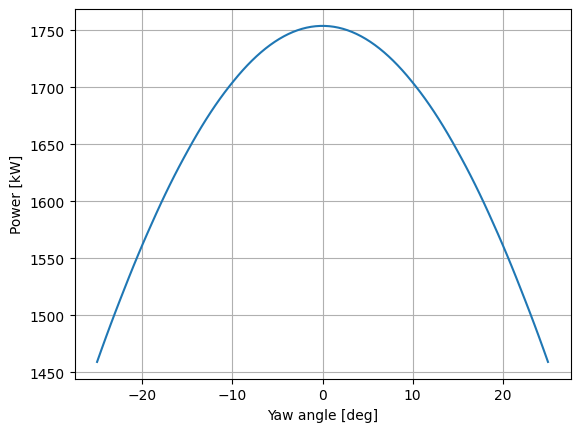

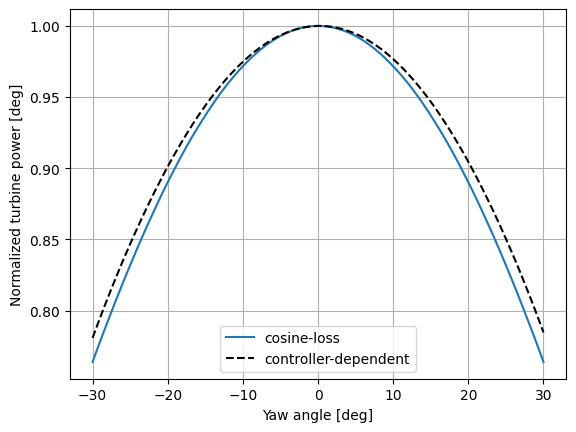

The "cosine-loss" operation model describes the decrease in power and thrust produced by a

wind turbine as it yaws (or tilts) away from the incoming wind. The thrust is reduced by a factor of

\(\cos \gamma\), where \(\gamma\) is the yaw misalignment angle, while the power is reduced by a factor

of \((\cos\gamma)^{p_P}\), where \(p_P\) is the cosine loss exponent, specified by cosine_loss_exponent_yaw.

Similarly, the thrust and power are reduced by factors of \((\cos \theta / \cos \theta_{ref})\) and

\((\cos \theta / \cos \theta_{ref})^{p_T}\), respectively, where \(\theta\) is the tilt angle,

\(\theta_{ref}\) is the reference tilt angle under which the power and thrust curves are specified, and

\(p_T\) is the cosine loss exponent for tilt, specified by cosine_loss_exponent_tilt.

The power and thrust produced by the turbine

thus vary as a function of the turbine's yaw angle, set using the yaw_angles argument to

FlorisModel.set(), and tilt angle (if applicable, for example for floating wind turbines).

from floris import TimeSeries

import numpy as np

import matplotlib.pyplot as plt

# Set up the FlorisModel

fmodel.set_operation_model("cosine-loss")

fmodel.set(layout_x=[0.0], layout_y=[0.0])

fmodel.set(

wind_data=TimeSeries(

wind_speeds=np.ones(100) * 8.0,

wind_directions=np.ones(100) * 270.0,

turbulence_intensities=0.06

)

)

fmodel.reset_operation()

# Sweep the yaw angles

yaw_angles = np.linspace(-25, 25, 100)

fmodel.set(yaw_angles=yaw_angles.reshape(-1,1))

fmodel.run()

powers = fmodel.get_turbine_powers()/1000

fig, ax = plt.subplots()

ax.plot(yaw_angles, powers)

ax.grid()

ax.set_xlabel("Yaw angle [deg]")

ax.set_ylabel("Power [kW]")

Text(0, 0.5, 'Power [kW]')

Simple derating model#

User-level name: "simple-derating"

Underlying class: SimpleDeratingTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)

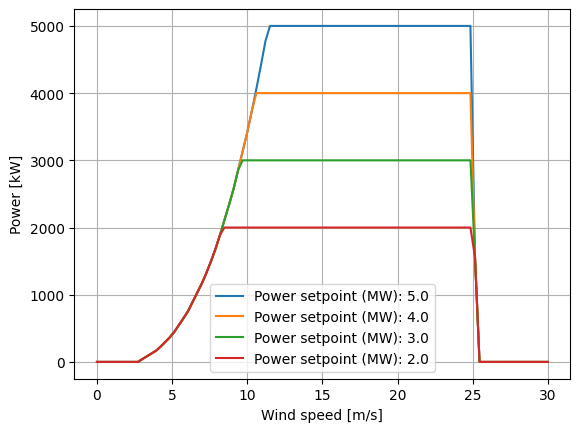

The "simple-derating" operation model enables users to derate turbines by setting a new power

rating. It does not require any extra parameters on the power_thrust_table, but adescribes the

decrease in power and thrust produced by providing the power_setpoints argument to

FlorisModel.set(). The default power rating for the turbine can be acheived by setting the

appropriate entries of power_setpoints to None.

# Set up the FlorisModel

fmodel.set_operation_model("simple-derating")

fmodel.reset_operation()

wind_speeds = np.linspace(0, 30, 100)

fmodel.set(

wind_data=TimeSeries(

wind_speeds=wind_speeds,

wind_directions=np.ones(100) * 270.0,

turbulence_intensities=0.06

)

)

fig, ax = plt.subplots()

for power_setpoint in [5.0, 4.0, 3.0, 2.0]:

fmodel.set(power_setpoints=np.array([[power_setpoint*1e6]]*100))

fmodel.run()

powers = fmodel.get_turbine_powers()/1000

ax.plot(wind_speeds, powers[:,0], label=f"Power setpoint (MW): {power_setpoint}")

ax.grid()

ax.legend()

ax.set_xlabel("Wind speed [m/s]")

ax.set_ylabel("Power [kW]")

/home/runner/work/floris/floris/floris/core/turbine/operation_models.py:358: RuntimeWarning: divide by zero encountered in divide

power_fractions = power_setpoints / base_powers

/home/runner/work/floris/floris/floris/core/wake_deflection/gauss.py:325: RuntimeWarning: invalid value encountered in divide

val = 2 * (avg_v - v_core) / (v_top + v_bottom)

/home/runner/work/floris/floris/floris/core/wake_deflection/gauss.py:160: RuntimeWarning: invalid value encountered in divide

C0 = 1 - u0 / freestream_velocity

/home/runner/work/floris/floris/floris/core/wake_velocity/gauss.py:80: RuntimeWarning: invalid value encountered in divide

sigma_z0 = rotor_diameter_i * 0.5 * np.sqrt(uR / (u_initial + u0))

Text(0, 0.5, 'Power [kW]')

Mixed operation model#

User-level name: "mixed"

Underlying class: MixedOperationTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)cosine_loss_exponent_yaw(scalar)cosine_loss_exponent_tilt(scalar)

The "mixed" operation model allows users to specify either yaw_angles (evaluated using the

"cosine-loss" operation model) or power_setpoints (evaluated using the "simple-derating"

operation model). That is, for each turbine, and at each findex, a non-zero yaw angle or a

non-None power setpoint may be specified. However, specifying both a non-zero yaw angle and a

finite power setpoint for the same turbine and at the same findex will produce an error.

fmodel.set_operation_model("mixed")

fmodel.set(layout_x=[0.0, 0.0], layout_y=[0.0, 500.0])

fmodel.reset_operation()

fmodel.set(

wind_data=TimeSeries(

wind_speeds=np.array([10.0]),

wind_directions=np.array([270.0]),

turbulence_intensities=0.06

)

)

fmodel.set(

yaw_angles=np.array([[20.0, 0.0]]),

power_setpoints=np.array([[None, 2e6]])

)

fmodel.run()

print("Powers [kW]: ", fmodel.get_turbine_powers()/1000)

Powers [kW]: [[3063.49046772 2000. ]]

AWC model#

User-level name: "awc"

Underlying class: AWCTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)helix_a(scalar)helix_power_b(scalar)helix_power_c(scalar)helix_thrust_b(scalar)helix_thrust_c(scalar)

The "awc" operation model allows for users to define active wake control strategies. These strategies

use pitch control to actively enhance wake mixing and subsequently decrease wake velocity deficits. As a

result, downstream turbines can increase their power production, with limited power loss for the controlled

upstream turbine. The AWCTurbine class models this power loss at the turbine applying AWC. For each

turbine, the user can define an AWC strategy to implement through the awc_modes array. Note that currently,

only "baseline", i.e., no AWC, and "helix", i.e., the

counterclockwise helix method have been implemented.

The user then defines the exact AWC implementation through setting the variable awc_amplitudes for

each turbine. This variable defines the mean-to-peak amplitude of the sinusoidal AWC pitch excitation,

i.e., for a turbine that under awc_modes = "baseline" has a constant pitch angle of 0 degrees, setting

awc_amplitude = 2 results in a pitch signal varying from -2 to 2 degrees over the desired Strouhal

frequency. This Strouhal frequency is not used as an input here, since it has minimal influence on turbine

power production. Note that setting awc_amplitudes = 0 effectively disables AWC and is therefore the same

as running a turbine at awc_modes = "baseline".

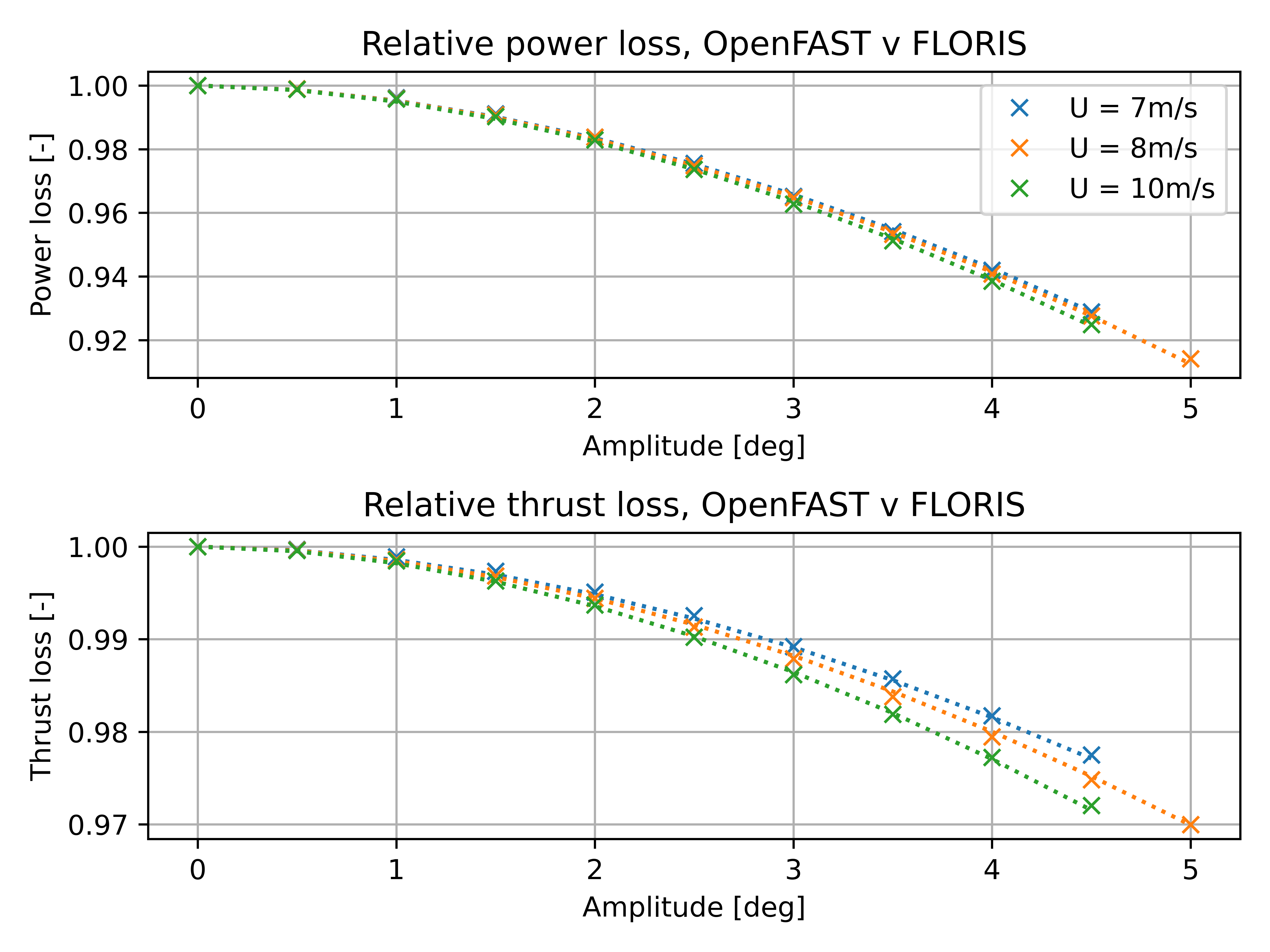

Each example turbine input file floris/turbine_library/*.yaml has its own helix_* parameter data. These

parameters are determined by fitting data from OpenFAST simulations in region II to the following equation:

where \(a\) is "helix_a", \(b\) is "helix_power_b", \(c\) is "helix_power_c", and \(A_\text{AWC}\) is awc_amplitudes.

The thrust coefficient follows the same equation, but with the respective thrust parameters. When AWC is

turned on while \(P_\text{baseline} > P_\text{rated}\), a warning is given as the model is not yet tuned for region III.

The figure below shows the fit between the turbine power and thrust in OpenFAST helix AWC simulations (x) and FLORIS simulations (--) at different region II wind speeds for the NREL 5MW reference turbine.

fmodel = FlorisModel("../examples/inputs/emgauss_helix.yaml")

fmodel.set_operation_model("awc")

fmodel.set(layout_x=[0.0, 0.0], layout_y=[0.0, 500.0])

fmodel.reset_operation()

fmodel.set(

wind_speeds=np.array([8.0]),

wind_directions=np.array([270.0]),

turbulence_intensities=np.array([0.06])

)

fmodel.set(

awc_modes=np.array([["helix", "baseline"]]),

awc_amplitudes=np.array([[2.5, 0]])

)

fmodel.run()

print("Powers [kW]: ", fmodel.get_turbine_powers()/1000)

Powers [kW]: [[6133.16222884 6301.1399872 ]]

Peak shaving model#

User-level name: "peak-shaving"

Underlying class: PeakShavingTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)peak_shaving_fraction(scalar)peak_shaving_TI_threshold(scalar)

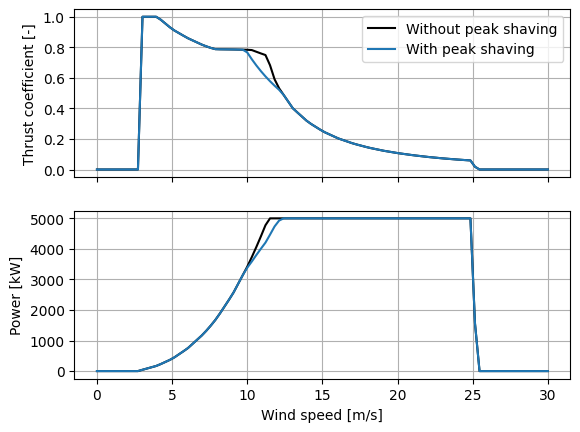

The "peak-shaving" operation model allows users to implement peak shaving, where the thrust

of the wind turbine is reduced from the nominal curve near rated to reduce unwanted structural

loading. Peak shaving here is implemented here by reducing the thrust by a fixed fraction from

the peak thrust on the nominal thrust curve, as specified by peak_shaving_fraction.This only

affects wind speeds near the peak in the thrust

curve (usually near rated wind speed), as thrust values away from the peak will be below the

fraction regardless. Further, peak shaving is only applied if the turbulence intensity experienced

by the turbine meets the peak_shaving_TI_threshold. To apply peak shaving in all wind conditions,

peak_shaving_TI_threshold may be set to zero.

When the turbine is peak shaving to reduce thrust, the power output is updated accordingly. Letting \(C_{T}\) represent the thrust coefficient when peak shaving (at given wind speed), and \(C_{T}'\) represent the thrust coefficient that the turbine would be operating at under nominal control, then the power \(P\) due to peak shaving (compared to the power \(P'\) available under nominal control) is computed (based on actuator disk theory) as

where \(a\) (respectively, \(a'\)) is the axial induction factor corresponding to \(C_T\) (respectively, \(C_T'\)), computed using the usual relationship from actuator disk theory, i.e. the lesser solution to \(C_T=4a(1-a)\).

# Set up the FlorisModel

fmodel = FlorisModel("../examples/inputs/gch.yaml")

fmodel.set(

layout_x=[0.0], layout_y=[0.0],

wind_data=TimeSeries(

wind_speeds=wind_speeds,

wind_directions=np.ones(100) * 270.0,

turbulence_intensities=0.2 # Higher than threshold value of 0.1

)

)

fmodel.reset_operation()

fmodel.set_operation_model("simple")

fmodel.run()

powers_base = fmodel.get_turbine_powers()/1000

thrust_coefficients_base = fmodel.get_turbine_thrust_coefficients()

fmodel.set_operation_model("peak-shaving")

fmodel.run()

powers_peak_shaving = fmodel.get_turbine_powers()/1000

thrust_coefficients_peak_shaving = fmodel.get_turbine_thrust_coefficients()

fig, ax = plt.subplots(2,1,sharex=True)

ax[0].plot(wind_speeds, thrust_coefficients_base, label="Without peak shaving", color="black")

ax[0].plot(wind_speeds, thrust_coefficients_peak_shaving, label="With peak shaving", color="C0")

ax[1].plot(wind_speeds, powers_base, label="Without peak shaving", color="black")

ax[1].plot(wind_speeds, powers_peak_shaving, label="With peak shaving", color="C0")

ax[1].grid()

ax[0].grid()

ax[0].legend()

ax[0].set_ylabel("Thrust coefficient [-]")

ax[1].set_xlabel("Wind speed [m/s]")

ax[1].set_ylabel("Power [kW]")

Text(0, 0.5, 'Power [kW]')

Controller-dependent model#

User-level name: "controller-dependent"

Underlying class: ControllerDependentTurbine

Required data on power_thrust_table:

rotor_solidity: (scalar)rated_rpm: (scalar)generator_efficiency: (scalar)rated_power: (scalar)rotor_diameter: (scalar)beta: (scalar)cd: (scalar)cl_alfa: (scalar)cp_ct_data_file: (string)

The "controller-dependent" operation model is an advanced operation model that uses the turbine's Cp/Ct

surface to optimize performance under yaw misalignment.

The "controller-dependent" operation model determines the wind turbine power output in yaw misalignment conditions, taking into account the effects of the control system.

When the rotor operates in below-rated conditions, the models assumes that blade pitch is equal to the optimal value (corresponding to maximum power coefficient \(C_P\)),

while the generator torque is scheduled as a function of rotational speed \(\omega\) according to the \(K\omega^2\) law.

The \(K\) coefficient is computed using the condition of maximum efficiency as shown in Chapter 7 of Hansen [4].

When the turbine operates above rated wind speed, the rotor speed is fixed and equal to the rated value, while the pitch angle is used to keep the power output equal to rated.

The "controller-dependent" operation model solves a balance equation between electrical power and aerodynamic power, assuming the aforementioned control strategies.

This yields the pitch and torque values that correspond to the current inflow and yaw misalignment. Based on these quantities, the power output of the turbine is computed.

Because the balance equation must be solved, the ControllerDependentTurbine is slower to execute than some other operation models.

The "controller-dependent" operation model considers the effect of vertical shear. Hence, the wind turbine can perform differently depending on the direction of misalignment.

Vertical shear is computed locally at each rotor, so it can be affected by wake impingement. The model includes both the effects of yaw and tilt on rotor performance.

To include the effects of shear, ensure that turbine_grid_points is greater than 1 in the main FLORIS configuration file.

The "controller-dependent" operation model requires the definition of some parameters that depend on the turbine:

Rated rotation speed (

rated_rpm), generator efficiency (generator_efficiency), and rated power, specified in kW (rated_power).Three parameters that describe the aerodynamics of the blade, namely

beta(twist),cd(drag) andcl_alfa(lift slope). These parameters are provided for the NREL 5MW, IEA 10MW, and IEA 15MW turbines in the "floris/turbine_library/". When using a different turbine model, these parameters can be estimated as shown in Section 3.5 of Tamaro et al. [5].Look-up tables of the power coefficient (\(C_P\)) and thrust coefficient \(C_T\) as functions of tip-speed ratio and blade pitch angle. Approximate values for these are provided for the reference turbines in "floris/turbine_library/".

Rotor solidity (

rotor_solidity), i.e. the fraction of the rotor area occupied by the blades.

Further details can be found in Tamaro et al. [5]. Developed and implemented by Simone Tamaro, Filippo Campagnolo, and Carlo L. Bottasso at Technische Universität München (TUM) (email: simone.tamaro@tum.de).

N = 101 # How many steps to cover yaw range in

yaw_max = 30 # Maximum yaw to test

# Set up the yaw angle sweep

yaw_angles = np.linspace(-yaw_max, yaw_max, N).reshape(-1,1)

# We can use the same FlorisModel, but we'll set it up for this test

fmodel.set(

wind_data=TimeSeries(

wind_speeds=np.ones(N) * 8.0,

wind_directions=np.ones(N) * 270.0,

turbulence_intensities=0.06

),

yaw_angles=yaw_angles,

)

# We'll compare the "controller-dependent" model to the standard "cosine-loss" model

op_models = ["cosine-loss", "controller-dependent"]

results = {}

for op_model in op_models:

print(f"Evaluating model: {op_model}")

fmodel.set_operation_model(op_model)

fmodel.run()

results[op_model] = fmodel.get_turbine_powers().squeeze()

fig, ax = plt.subplots()

colors = ["C0", "k"]

linestyles = ["solid", "dashed"]

for key, c, ls in zip(results, colors, linestyles):

central_power = results[key][yaw_angles.squeeze() == 0]

ax.plot(yaw_angles.squeeze(), results[key]/central_power, label=key, color=c, linestyle=ls)

ax.grid(True)

ax.legend()

ax.set_xlabel("Yaw angle [deg]")

ax.set_ylabel("Normalized turbine power [deg]")

floris.logging_manager.LoggingManager WARNING Cp/Ct data provided with FLORIS is for demonstration purposes only, and may not accurately reflect the actual Cp/Ct surfaces of reference wind turbines.

Evaluating model: cosine-loss

Evaluating model: controller-dependent

Text(0, 0.5, 'Normalized turbine power [deg]')

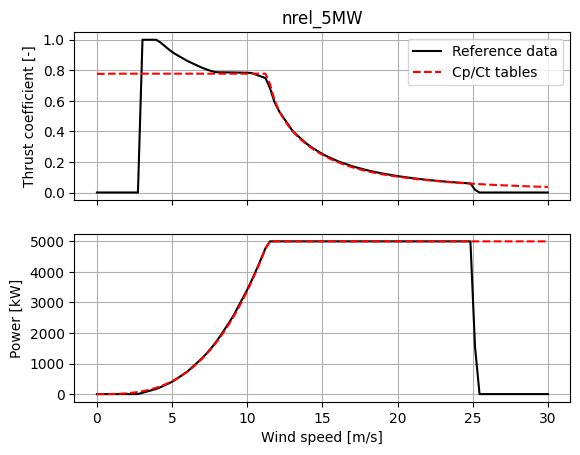

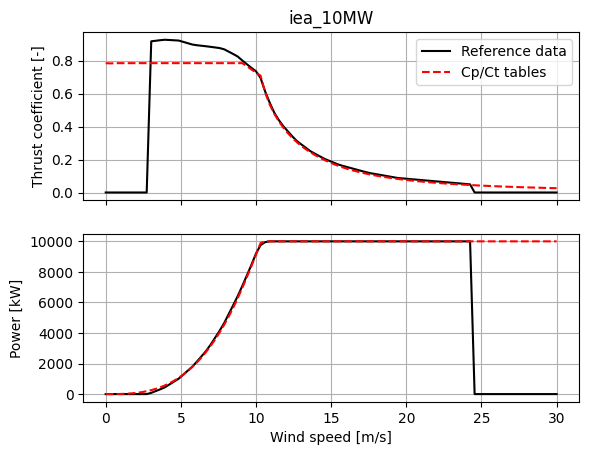

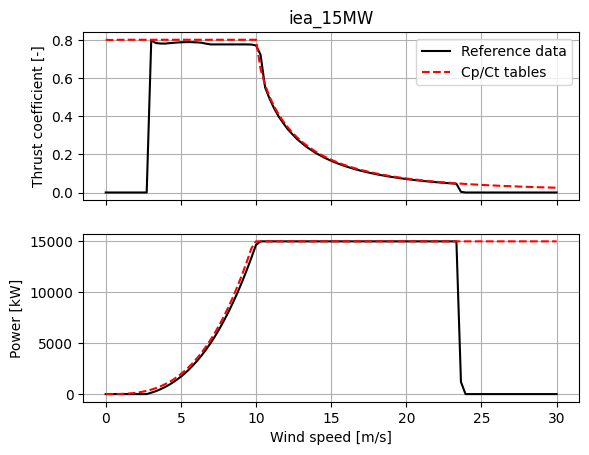

WARNING: The power and thrust curves generated by querying tabulated data as a function of blade pitch and tip-speed ratio for the reference wind turbines is not an exact match for the reference power and thrust curves found at the IEA Wind Task 37's Github page or the NREL 5MW reference data. As such, results using the Controller-dependent model, which rely on these \(C_P\) and \(C_T\) tables, should be considered demonstrative only and not necessarily consistent with other results using the reference wind turbines.

For example, the nominal power and thrust curves for the IEA 15MW, IEA 10MW, and NREL 5MW are shown below, along with their derivations from the provided demonstrative \(C_P\) / \(C_T\) tables.

fmodel.reset_operation()

for turbine in ["nrel_5MW", "iea_10MW", "iea_15MW"]:

fmodel.set(

layout_x=[0.0], layout_y=[0.0], turbine_type=[turbine],

wind_data=TimeSeries(

wind_speeds=wind_speeds,

wind_directions=np.ones(100) * 270.0,

turbulence_intensities=0.2 # Higher than threshold value of 0.1

)

)

# Simple model (using reference power and thrust curves)

fmodel.set_operation_model("simple")

fmodel.run()

P_s = fmodel.get_turbine_powers()/1000

CT_s = fmodel.get_turbine_thrust_coefficients()

# Controller-dependent model (using demonstration Cp/Ct tables)

fmodel.set_operation_model("controller-dependent")

fmodel.run()

P_cd = fmodel.get_turbine_powers()/1000

CT_cd = fmodel.get_turbine_thrust_coefficients()

fig, ax = plt.subplots(2,1,sharex=True)

ax[0].plot(wind_speeds, CT_s, label="Reference data", color="black")

ax[0].plot(wind_speeds, CT_cd, label="Cp/Ct tables", color="red", linestyle="--")

ax[1].plot(wind_speeds, P_s, label="Reference data", color="black")

ax[1].plot(wind_speeds, P_cd, label="Cp/Ct data", color="red", linestyle="--")

ax[1].grid()

ax[0].grid()

ax[0].legend()

ax[0].set_ylabel("Thrust coefficient [-]")

ax[1].set_xlabel("Wind speed [m/s]")

ax[1].set_ylabel("Power [kW]")

ax[0].set_title(turbine)

floris.logging_manager.LoggingManager WARNING Cp/Ct data provided with FLORIS is for demonstration purposes only, and may not accurately reflect the actual Cp/Ct surfaces of reference wind turbines.

floris.floris_model.FlorisModel WARNING turbine_type has been changed without specifying a new reference_wind_height. reference_wind_height remains 90.00 m. Consider calling `FlorisModel.assign_hub_height_to_ref_height` to update the reference wind height to the turbine hub height.

floris.logging_manager.LoggingManager WARNING Cp/Ct data provided with FLORIS is for demonstration purposes only, and may not accurately reflect the actual Cp/Ct surfaces of reference wind turbines.

/home/runner/work/floris/floris/floris/core/turbine/controller_dependent_operation_model.py:438: RuntimeWarning: invalid value encountered in divide

u_u_hh = mean_speed / mean_speed[int(np.floor(len(mean_speed) / 2))]

/home/runner/work/floris/floris/floris/core/turbine/controller_dependent_operation_model.py:956: RuntimeWarning: invalid value encountered in sqrt

(1 + np.sqrt(1 - x - 1 / 16 * x**2 * sinMu**2))

/home/runner/work/floris/floris/floris/core/turbine/controller_dependent_operation_model.py:329: RuntimeWarning: The iteration is not making good progress, as measured by the

improvement from the last ten iterations.

ct = fsolve(ControllerDependentTurbine.get_ct, x0, args=data) # Solves eq. (25)

/home/runner/work/floris/floris/floris/core/turbine/controller_dependent_operation_model.py:355: RuntimeWarning: The iteration is not making good progress, as measured by the

improvement from the last ten iterations.

ct = fsolve(ControllerDependentTurbine.get_ct, x0, args=data) # Solves eq. (25)

Powers more than 1% above rated detected. Consider checking Cp-Ct data.

floris.floris_model.FlorisModel WARNING turbine_type has been changed without specifying a new reference_wind_height. reference_wind_height remains 90.00 m. Consider calling `FlorisModel.assign_hub_height_to_ref_height` to update the reference wind height to the turbine hub height.

floris.logging_manager.LoggingManager WARNING Cp/Ct data provided with FLORIS is for demonstration purposes only, and may not accurately reflect the actual Cp/Ct surfaces of reference wind turbines.

floris.floris_model.FlorisModel WARNING turbine_type has been changed without specifying a new reference_wind_height. reference_wind_height remains 90.00 m. Consider calling `FlorisModel.assign_hub_height_to_ref_height` to update the reference wind height to the turbine hub height.

floris.logging_manager.LoggingManager WARNING Cp/Ct data provided with FLORIS is for demonstration purposes only, and may not accurately reflect the actual Cp/Ct surfaces of reference wind turbines.

Powers more than 1% above rated detected. Consider checking Cp-Ct data.

Unified Momentum Model#

User-level name: "unified-momentum"

Underlying class: UnifiedMomentumModelTurbine

Required data on power_thrust_table:

ref_air_density(scalar)ref_tilt(scalar)wind_speed(list)power(list)thrust_coefficient(list)

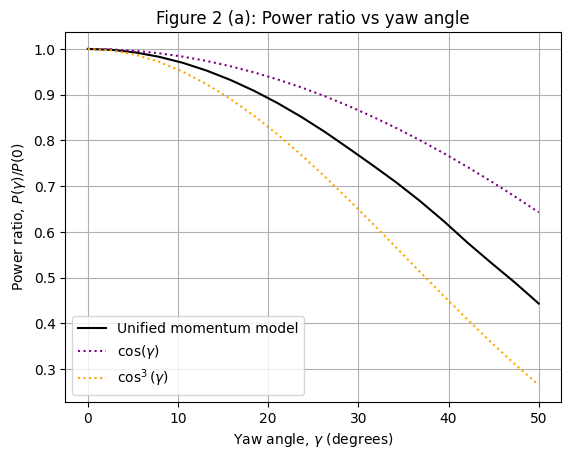

An extension of the classical one-dimensional momentum theory to model the induction of an actuator disk is presented in K.S. Heck and Howland [6] to directly account for power and thrust loss due to yaw misalignment rather than using an empirical correction as in the cosine loss model. Analytical expressions for the induction, thrust, initial wake velocities and power are developed as a function of the yaw angle and thrust coefficient.

Note that the low thrust limit of the Unified Momentum Model is presently implemented in FLORIS, which returns the equations derived and validated in Heck et al. (2023). This low thrust limit will be accurate for thrust coefficients approximately less than 0.9.

This section recreates key validation figures discussed in the paper through FLORIS.

n_points = 20

fmodel.set_operation_model("unified-momentum")

fmodel.set(layout_x=[0.0], layout_y=[0.0], turbine_type=["nrel_5MW"])

fmodel.reset_operation()

fmodel.set(

wind_data=TimeSeries(

wind_speeds=np.array(n_points * [11.0]),

wind_directions=np.array(n_points * [270.0]),

turbulence_intensities=0.06

)

)

yaw_angles = np.linspace(0, 50, n_points)

cos_reference = np.cos(np.radians(yaw_angles))

cos3_reference = np.cos(np.radians(yaw_angles))**3

fmodel.set(yaw_angles=np.reshape(yaw_angles, (-1,1)))

fmodel.run()

powers = fmodel.get_turbine_powers()

power_ratio_umm = powers[:,0] / powers[0,0]

fig, ax = plt.subplots(1,1)

ax.plot(yaw_angles, power_ratio_umm, label="Unified momentum model", color="black")

ax.plot(yaw_angles, cos_reference, label=r"$\cos(\gamma)$", linestyle=":", color="purple")

ax.plot(yaw_angles, cos3_reference, label=r"$\cos^3(\gamma)$", linestyle=":", color="orange")

ax.grid()

ax.legend()

ax.set_title("Figure 2 (a): Power ratio vs yaw angle")

ax.set_xlabel(r"Yaw angle, $\gamma$ (degrees)")

ax.set_ylabel(r"Power ratio, $P(\gamma)/P(0)$")

floris.floris_model.FlorisModel WARNING turbine_type has been changed without specifying a new reference_wind_height. reference_wind_height remains 90.00 m. Consider calling `FlorisModel.assign_hub_height_to_ref_height` to update the reference wind height to the turbine hub height.

Text(0, 0.5, 'Power ratio, $P(\\gamma)/P(0)$')

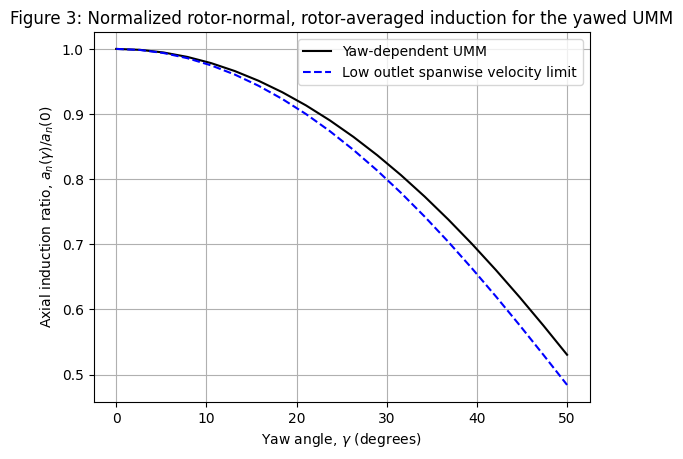

from floris.core.turbine.unified_momentum_model import Heck, LimitedHeck

n_points = 20

yaw_angles = np.linspace(0, 50, n_points)

ct_prime = 1.33

heck = Heck()

ai_umm = np.array([heck(ct_prime, np.radians(yaw)).an for yaw in yaw_angles])

heck_no_spanwise = LimitedHeck()

ai_no_spanwise = np.array([heck_no_spanwise(ct_prime, np.radians(yaw)).an for yaw in yaw_angles])

fig, ax = plt.subplots(1,1)

ax.plot(yaw_angles, ai_umm / ai_umm[0], label="Yaw-dependent UMM", color="black")

ax.plot(yaw_angles, ai_no_spanwise/ ai_no_spanwise[0], label="Low outlet spanwise velocity limit", linestyle="--", color="blue")

ax.grid()

ax.legend()

ax.set_title("Figure 3: Normalized rotor-normal, rotor-averaged induction for the yawed UMM")

ax.set_xlabel(r"Yaw angle, $\gamma$ (degrees)")

ax.set_ylabel(r"Axial induction ratio, $a_n(\gamma) / a_n(0)$")

Text(0, 0.5, 'Axial induction ratio, $a_n(\\gamma) / a_n(0)$')