Controllers#

The whoc.controllers module contains a library of wind and hybrid power plant

controllers. Each controller must inherit from ControllerBase (see

controller_base.py) and implement a

mandatory compute_controls() method, which contains the relevant control

algorithm. compute_controls() must accept a single argument dictionary

(nominally called measurement_dict) that contains the necessary input

signals and return a second dictionary (nominally called controls_dict) that

returns the control actions. In the basic set up, measurement_dict is

provided to compute_controls() by the step() method defined on

ControllerBase, and the returned controls_dict is then passed via the

interface at the conclusion of the step() method.

Available controllers#

LookupBasedWakeSteeringController#

Yaw controller that implements wake steering based on a lookup table.

Requires a df_opt object produced by a FLORIS yaw optimization routine. See example

lookup-based_wake_steering_florisstandin for example usage.

Currently, yaw angles are set based purely on the (local turbine) wind direction. The lookup table is sampled at a hardcoded wind speed of 8 m/s. This will be updated in future when an interface is developed for a simulator that provides wind turbine wind speeds also.

WakeSteeringROSCOStandin#

Not yet developed. May be combined into a universal simple LookupBasedWakeSteeringController.

WindFarmPowerDistributingController#

Wind farm-level power controller that simply distributes a farm-level power reference between wind turbines evenly, without checking whether turbines are able to produce power at the requested level. Not expected to perform well when wind turbines are waked or cannot produce the desired power for other reasons. However, is a useful comparison case for the WindFarmPowerTrackingController (described below).

WindFarmPowerTrackingController#

Closed-loop wind farm-level power controller that distributes a farm-level power reference among the wind turbines in a farm and adjusts the requests made from each turbine depending on whether the power reference has been met. Developed under the A2e2g project, with further details provided in Sinner et al..

Integral action, as well as gain scheduling based on turbine saturation, has been disabled as

simple proportional control appears sufficient currently. However, these may be enabled at a

later date if needed. The proportional_gain for the controller may be provided on instantiation,

and defaults to proportional_gain = 1.

HybridSupervisoryControllerBaseline#

Simple closed-loop supervisory controller for a hybrid wind/solar/battery plant. Reads in current power production from wind, solar, and battery, as well as a plant power reference. Contains logic to determine technology set points for wind, solar and battery technologies to follow the plant power reference. The control is based on a proportional gain based on the error between the wind and solar production and the plant power reference. The controller increases the power references sent to wind, solar, and battery if the power reference is not met. If there is a power surplus from wind and solar, the controller adjusts the power reference values to charge the battery up to the battery capacity.

The power reference values for wind, solar and battery technologies are then handled by the operational controllers for wind, solar, and battery, which are assigned to the HybridSupervisoryControllerBaseline on instantiation to distribute the bulk references to each asset amongst the individual generators. Currently, only wind actually distributes the power.

Intended as a baseline for comparison to more advanced supervisory controllers.

This controller can also be run for a hybrid plant comprising wind or solar

and/or a battery. At least one of the wind or solar components must be present,

with the battery component optional. Upon instantiation, the user may set

wind_controller, solar_controller, and/or battery_controller to None if

no wind, solar, and/or battery component is available, respectively.

BatteryController#

Controller to trade off battery demand response with battery degradation. The

BatteryController takes as an input the higher-level battery power reference,

and produces a modified (“input-shaped”) reference with the intention of

reducing wear and tear on the battery. Designed to create a second-order closed-loop

system response to reference inputs.

Generally speaking, increasing the controller gain k_batt increases the natural

frequency of the second-order system response, and if increased too far, can lead to

instability. The default value for k_batt is 0.1.

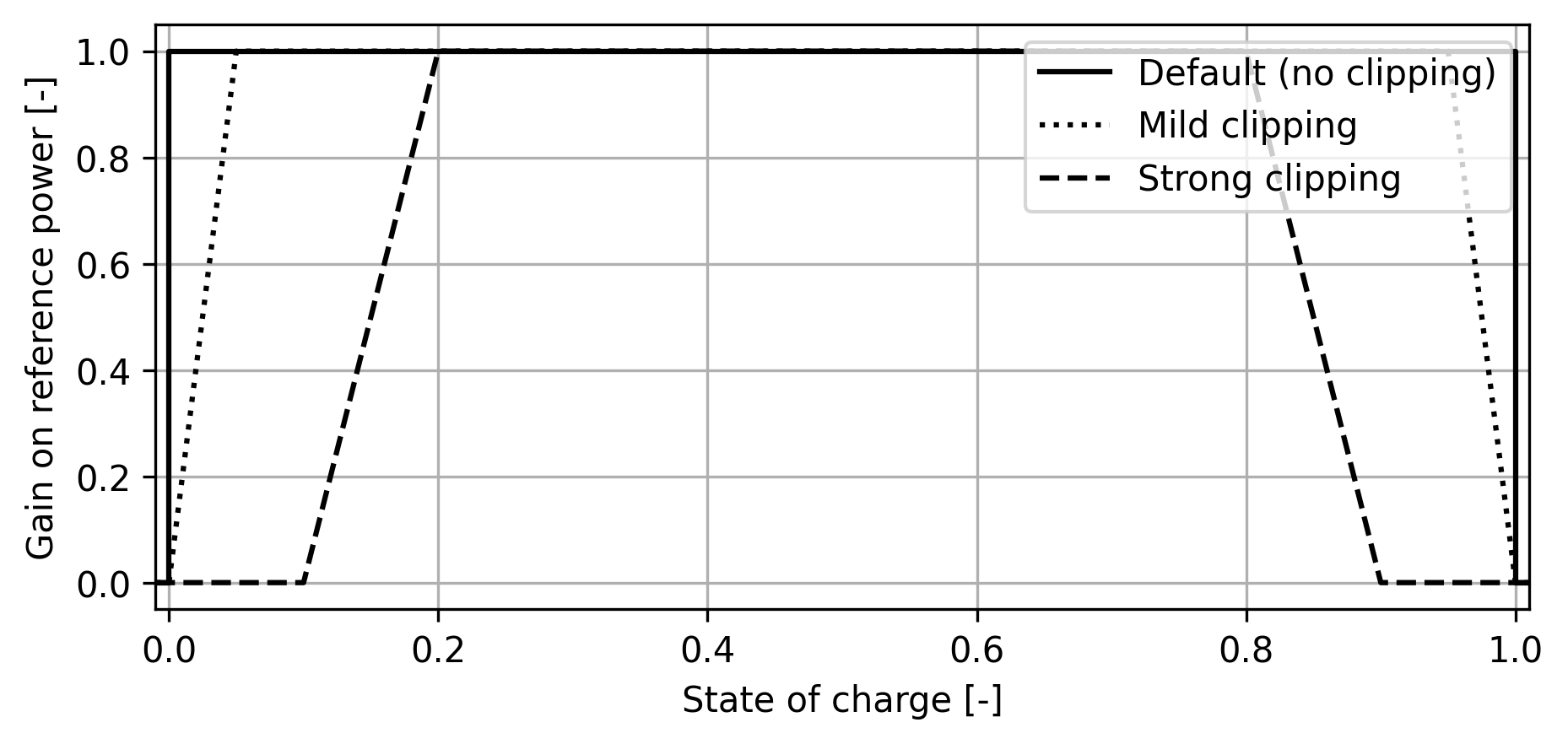

The BatteryController also enables clipping of the reference to throttle the

battery at high and low states of charge (SOC). This throttling is applied by specifying

four SOC thresholds between 0 and 1: below the first threshold, the reference is nullified;

between the first and second, the output reference is linearly ramped up; between the second

and third, the full reference is used; between the third and fourth, the output reference is

linearly ramped down; and above the fourth, the reference is again nullified. Examples of

this are shown below. These are specified by passing a four-element list of fractional

SOCs to

clipping_thresholds, e.g. clipping_thresholds=[0.1, 0.2, 0.8, 0.9].

The default is to apply the full reference across the full range of SOCs, i.e.

clipping_thresholds=[0, 0, 1, 1].

HydrogenPlantController#

Simple closed-loop controller for an off-grid power generation/hydrogen plant. The controller uses an external hydrogen reference signal to control the hydrogen production of the plant through setting the power reference signal.

Reads in current power production from the generator(s), the current hydrogen production rate, and the hydrogen rate reference. Contains logic to set the generator power reference using a proportional gain applied to the error between the current hydrogen production rate and the hydrogen production reference. The proportional gain is scaled by the current power production to handle the difference of several magnitudes between the power and the hydrogen production rate.

The power reference computed is then passed to a secondary power generation plant controller, which is assigned to the HydrogenPlantController on instantiation.

This secondary power generation controller could be WindFarmPowerTrackingController for a wind-only plant, HybridSupervisoryControllerBaseline for a hybrid generation plant, etc.